A Biased View of 24??media

A Biased View of 24??media

Blog Article

An Unbiased View of 24??media

Table of ContentsAll About 24??mediaThe Facts About 24??media RevealedThe Best Guide To 24??mediaThe 3-Minute Rule for 24??mediaFascination About 24??media

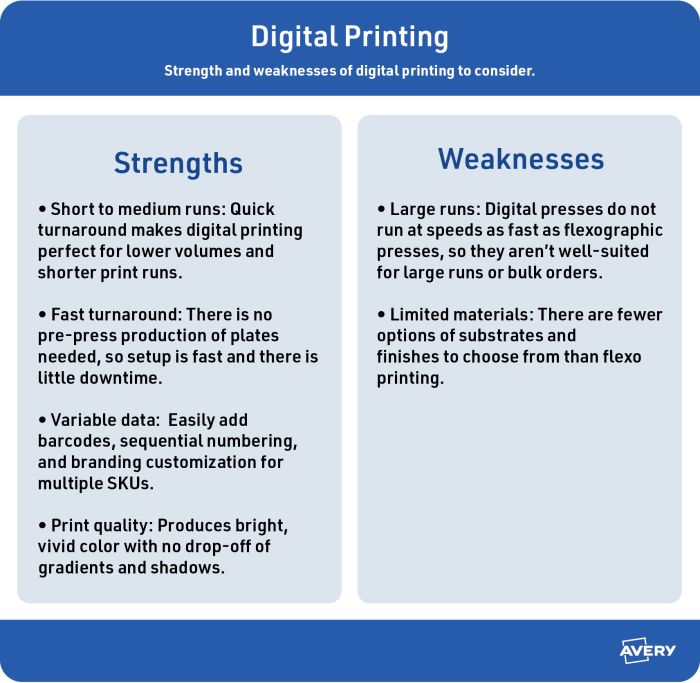

Innovations in print innovation are altering the interactions playing area when it involves top quality, cost and sophisticated abilities. Offset printing and digital printing are the significant procedures whereby print jobs are embarked on both making use of four-color printing methods. Each option has its benefits, providing different strategies to satisfy the needs of varied manufacturing projects.

Generally, this has actually been the most consistent technique for precisely preserving color matches, making it perfect for print runs that only need fixed printing such as pre-printed forms, pamphlets, leaflets, service cards, and mass postcard mailings. Due to the fixed nature of litho printing, it is not suitable for variable print pieces that will certainly be sent by mail to private receivers such as declarations, letters, and customized postcards.

The Greatest Guide To 24??media

The newest innovations in print technology are assisting to bring numerous of countered's benefits into the electronic printing world really transforming the face of modern printing! There are some key differences between Offset Printing and Digital Printing.

Today's electronic print tools is amongst the most sophisticated on the market. Here are several of the largest advantages of making use of electronic printing: dominate the digital print area, with full-color printing finished in one procedure and effortlessly printed straight from a print file. Without an extensive set up process, the calibration time of a particular work is reduced, contributing to quicker print time and overall delivery.

The inkjet printing process has assisted to transform the industry in addition to the high quality and speed of the outcome. The latest inkjet technology can print on conventional countered stocks with plain, silk, and shiny coatings. High-grade electronic print paired with software-managed shade management techniques adds maximum value to print items and makes production processes a lot more reliable than offset.

Unknown Facts About 24??media

(https://pastebin.com/u/za24media)

Eco-friendly and naturally degradable inks and toners are also offered for even more sustainable printing. Digital print likewise gets rid of the demand to clean plates or blankets with dangerous chemicals at the end of the printing process.

Variable information aids organizations reach their specific clients and audience with uniquely-created and customized web content. As innovation enhances, the quality of electronic printing has actually come to be second-to-none, with better information, color suit abilities and general precision. Without the need to wash plates or make use of excess ink, digital printing is likewise much less inefficient and usually more eco friendly.

("flexo"), involve several click now make-ready actions to transfer an original image to a substratum.

24??media Fundamentals Explained

Digital printing, with fewer relocating items, is more agile than countered in this regard.

Minimized set-up time saves money on the front end. And since these are not enormous mass orders, smaller sized businesses can manage to publish without having to satisfy the higher and more pricey print limits of conventional printing.

Make sure you work together with a printing and product packaging partner that has the ideal certifications. While eleventh-hour printing and customization are a massive advantage, electronic may not always be the most effective technique for you. For instance, offset printing has the benefit of cost-effectiveness with big print runs, especially those with innovative ornamental effects and specialty layers.

24??media Things To Know Before You Buy

The positive plate, with its smooth surface, draws in oil-based inks and fends off water. In comparison, the unfavorable plate, with its harsh structure, absorbs water and wards off oil. Rubber rollers are after that used to transfer the image from the plate to the corrugated surface.

Corrugated paper can sometimes confirm to be a difficult surface area to publish on, however Litho prints to a different surface and is after that laminated flooring to it, making it very easy to print top quality pictures. It can be incredibly consistent, also for futures. Actually, the more you print, the less expensive the costs become for Litho.

If you have adequate time and budget plan, and a huge volume of a single layout, after that there shouldn't be a problem. What Litho doesn't give you is specifically what Digital does, customization. Much more on that later on. Expensive established Longer turn-around No Variable Information Printing Smaller sized shade gamut, shades can be less bright Digital printing is the process of printing digital pictures straight onto the corrugated substratum using a single-pass, direct-to-corrugate strategy - Point of sale stands.

Report this page